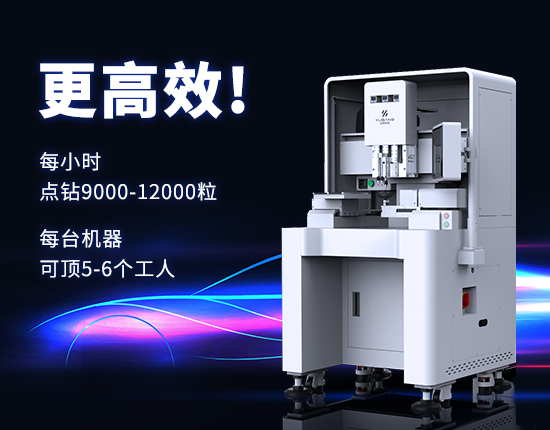

自动蜡镶点钻机自动点钻效率高

高效率是激烈的市场竞争环境下的有利条件,传统的首饰加工行业更是如此。蜡镶加工是首饰加工里非常重要的一个环节,传统的蜡镶都是依靠人工,不仅效率低而且产能非常受限。

自动蜡镶点钻机自动点钻效率高,三个吸头同时开工,每小时产能高达12000粒,是人工的5-6倍。对于平面微曲面的简单款式更是高达每小时14000粒,一小时就能完成人工一天的量,一天就能完成人工一周的量,效率不仅提高,产能也随之大大提高了。

自动蜡镶点钻机的高效率也体现在返工率的减少上,因为它的智能识别不漏钻功能,能够自动补充漏石,让蜡模上的每个石位都能填满,保证出品不漏石,大大减少了因为漏石而要人工补石的工作。

自动蜡镶点钻机的出现使得自动点钻成为可能,不仅给蜡镶加工注入了新的活力,更使得蜡镶加工摆脱效率低产能低的局面。

创建时间:2023-08-14 14:56

넶浏览量:0