蜡镶机该如何有效进行保养?

再好的设备也需要保养,及时得当的保养,对于设备的正常运行以及延长使用寿命至关重要。蜡镶机作为首饰品加工行业得力助手,下面将介绍玉邦高智能蜡镶机的保养方法,帮助您更好地维护和使用这台机器。

首先,润滑是保养蜡镶机的重要手段之一,需要定期给蜡镶机各轴的导杆和丝杆刷润滑油。蜡镶机需要使用专业润滑油进行润滑,以减少部件之间的摩擦和磨损,这里建议每月2次,也可根据机器使用频率来减少或增加次数。在使用润滑油时,应按照说明书上的使用方法进行操作,避免过量使用或使用不当导致机器故障。

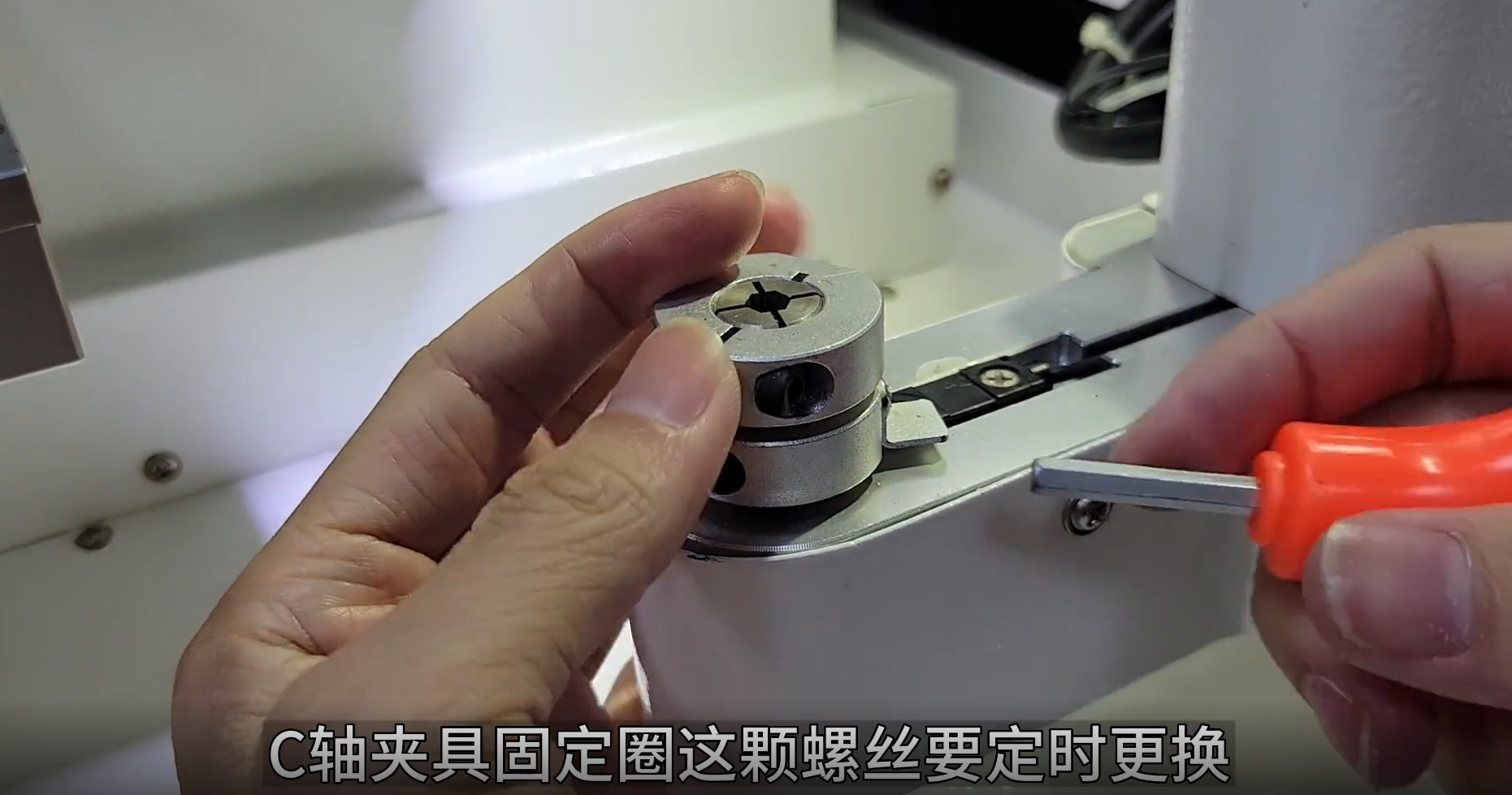

其次,定期检查是保养蜡镶机的基础。检查的内容包括设备的各个部件是否正常运转、设备的连接部位是否紧固,以避免因松动而引起的故障。这里强调的是,C轴固定圈的螺丝需要定期更换,因为这个部位经常要取换固定模具,所以很容易松动。

第三,气压表上的气动真空过滤器需要定期清理。因为蜡镶机是运用气体的吸力和喷力工作的,所以运气的管子上需要过滤杂质,定期清理过滤器能使得蜡镶机更快速点钻。

第四,空压机和过滤器内的污水需要定期排放。因为蜡镶机是电驱气动装置,需要空压机制造气压带动蜡镶机,而过滤器则用来过滤气体里的杂质和水。所以需要定期清理这两个装置。

保持蜡镶机的清洁是保养的重要环节。在生产过程中,机器表面会沾有大量灰尘,因此需要定期进行清洁,可以使用柔软的布擦拭机器表面。

最后,保养蜡镶机还需注意安全问题。在使用机器时,必须遵守安全操作规程,当蜡镶机在高速运作的时候,不要触及各个轴。使用过程中,如发现异常及时联系售后处理。玉邦科技拥有一支极具专业与耐心的售后服务团队,响应迅速,让您售后无忧。

总之,保养蜡镶机需要正确润滑、定期检查、保持清洁、以及注意安全问题等多方面。只有通过正确的保养和维护,才能保证蜡镶机的正常运行并延长其使用寿命。