为什么要选择电驱式的蜡镶点钻机?

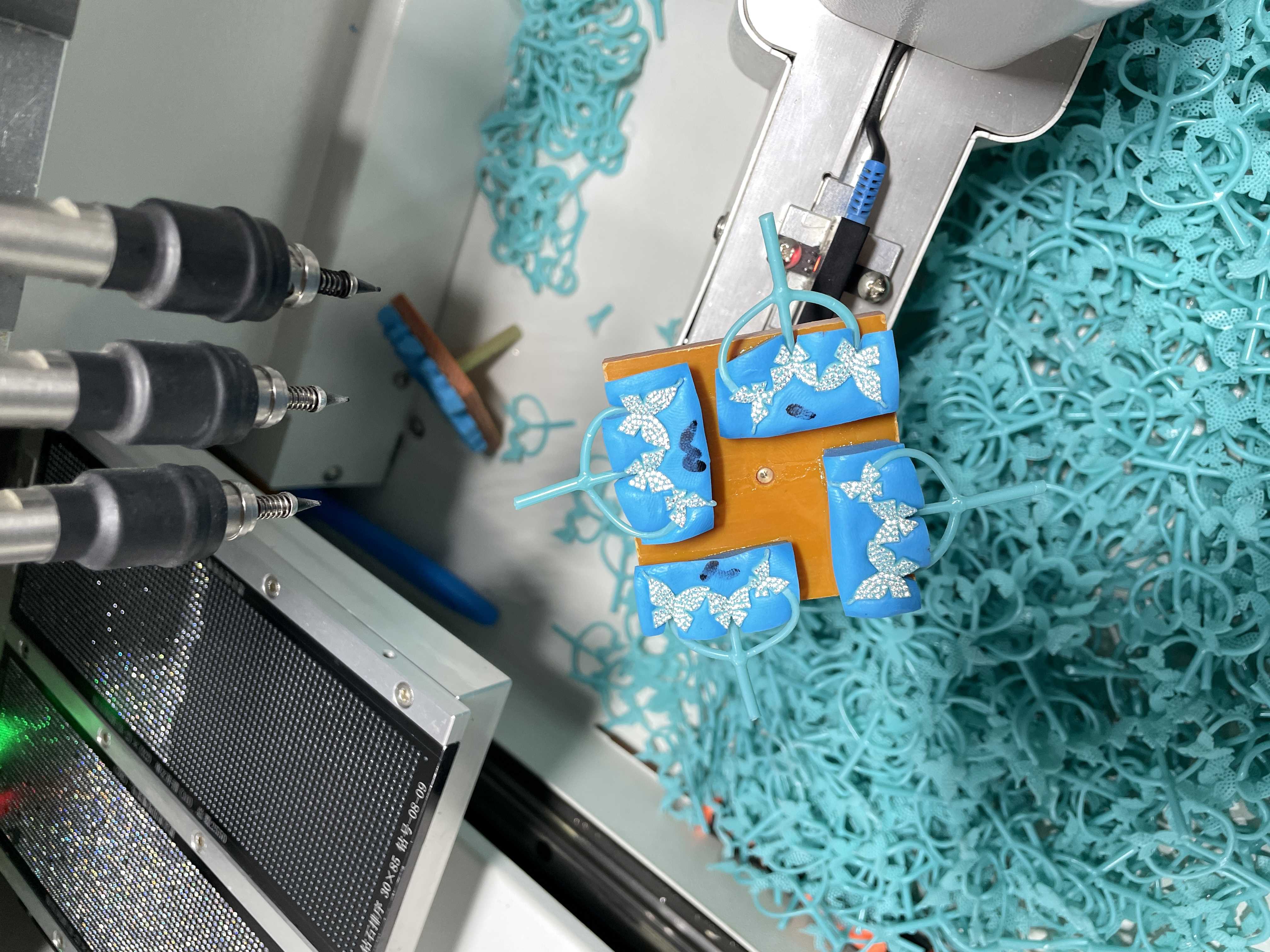

蜡镶点钻机是首饰加工的蜡镶环节里不可或缺的一款设备,是蜡镶加工的好帮手!市面上的自动蜡镶点钻机,有电驱式和气动式,建议在选择蜡镶机的时候,优先选择电驱动式的。

为什么要选择电驱式的蜡镶点钻机呢?

首先,电驱式的蜡镶机比较稳定。稳定性强是电驱式蜡镶机的一大优点。玉邦科技的电驱式蜡镶点钻机,插上电,就可以完成平稳、精准的镶石点钻工作了。而且玉邦科技的蜡镶机,支持24小时不停机,长时间打货,机器也不会出现偏位情况,出品质量非常的稳定。

其次,电驱式镶石,在蜡镶机正常打货模式下,力度控制得恰当好处,非常精准,采用的是柔性按压方式镶石。都知道,用来镶石的蜡模本身是非常脆的,如果是非电驱式的直冲下针镶石,很容易把蜡模的石位打坏。电驱式镶石出品,则会确保不伤蜡模不伤石,最大程度还原了蜡模和石头的完整性。

最后,采用电驱式镶石的蜡镶点钻机,用电量和用气量都非常小,在机器正常运转的情况下,每次启动所需的电和气都能实现最大化利用,节约消耗成本。

因此,选择电驱式的蜡镶点钻机是实现点钻利益最大化的有效方式!

你还想知道关于蜡镶点钻机的哪些问题,欢迎评论区留言!

创建时间:2024-09-21 10:26

넶浏览量:0