why large quantities of wax inlay must use automatic wax inlay machine?

in the jewelry processing industry, the traditional wax inlay processing method has been relying on manual completion. However, in today's competitive market environment, efficiency and quality have become the key factors to determine the market competitiveness. Especially in the face of high-volume wax inlay demand, the application of automation technology becomes particularly important.

Significantly improve work efficiency

Waxsetting machine greatly improves the production efficiency. A standard configuration of the automatic wax insert point drilling machine can complete the equivalent the amount of work done by 8 to 10 wax inserts. When the order volume increases greatly, this automated solution not only accelerates the inlay process, but also ensures the continuity and consistency of the wax inlay work, making the entire jewelry production process more smooth and efficient.

guarantee product quality

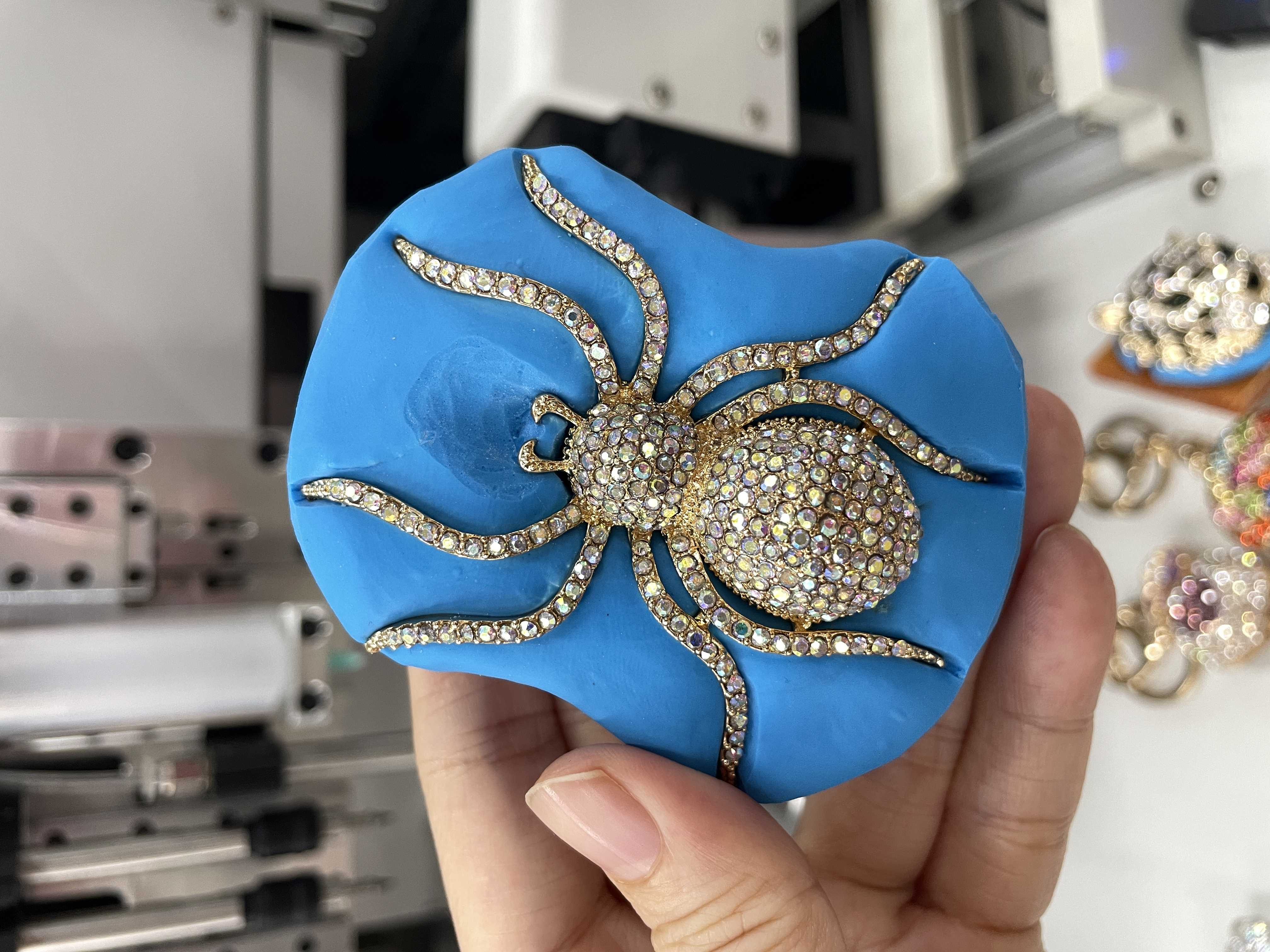

In addition to the advantages of wax insert point drilling speed, the automatic intelligent wax insert machine can also provide higher quality wax insert products. Since the operation of the wax setting machine is based on pre-set programming, errors caused by human factors can be almost avoided. In particular, the intelligent 3D wax setting machine produced by Yubang Technology is equipped CNC precision control system, to achieve up to 0.01mm level of point drilling accuracy control. Even when the machine is running at high speed, it can maintain stable performance and ensure that every piece of jewelry is up to the standard of precision work.

Effectively reduce rework rate

for large-scale jewelry wax inlay, one of the most troublesome problems is the production of non-conforming products and the subsequent repair work. The common leakage phenomenon in traditional manual wax inlay has been effectively solved after the use of Yubang high intelligent wax inlay machine. The equipment has advanced intelligent identification and no leakage drilling function, which can automatically detect and supplement any leakage stone, thus ensuring that each wax inlaid work can reach 100 full stone effect, thus fundamentally eliminating the need for manual rework due to quality problems.

In short, the automatic wax setting machine not only changes the manual operation mode of the jewelry manufacturing industry, but also sets a new benchmark for the jewelry processing industry by improving work efficiency and product quality. It marks the wax inlay process is moving towards a more modern, intelligent direction.

If you are interested in wax setting machine or want to know more about it, please pay attention to us! Yubang Technology is a jewelry processing equipment manufacturer with 20 years of experience, providing you with one-stop technical solutions for jewelry processing.