为什么说智能蜡镶机能确保出品不漏钻?

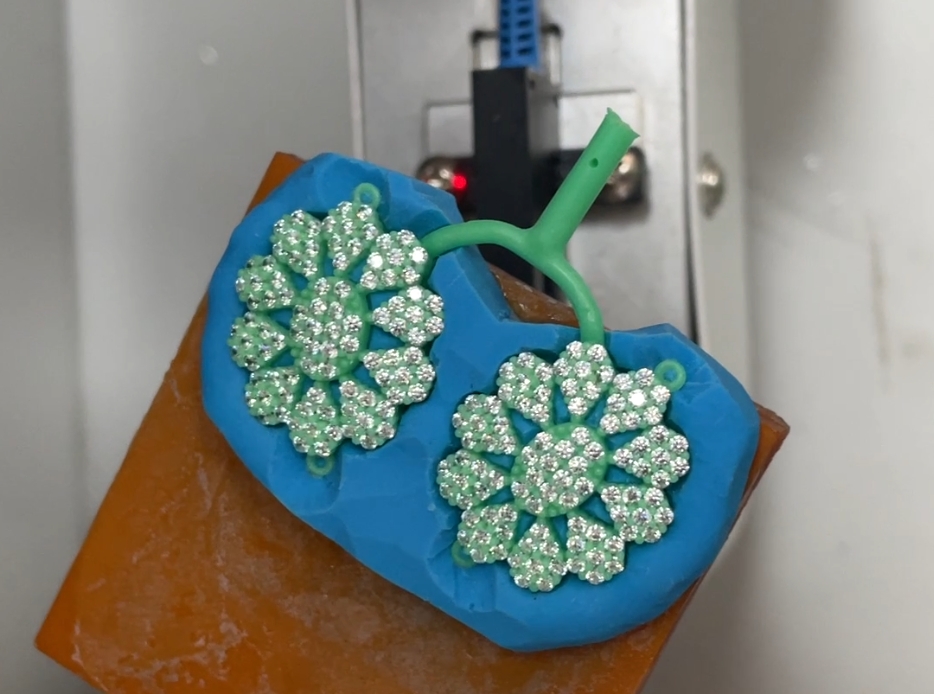

在蜡镶首饰的成品工艺流程中,传统的点钻镶嵌主要依赖手工操作。然而,随着消费者需求的不断提升,大规模生产仅靠人工变得愈发困难。智能蜡镶机的出现,使得批量生产变得轻松自如。

大家都知道智能蜡镶机的速度令人惊叹,但它的智能化体现在哪些方面呢?传统的人工点钻镶嵌存在一个显著的问题:容易漏钻。由于需要镶嵌的钻石通常极其微小,工人长时间凝视这些精密物件时,很容易 “眼花缭乱”,导致空钻或漏钻。

智能蜡镶机则能够有效避免这一问题。它能自动检测料盘上是否有钻石,当吸嘴未能吸取到钻石时,会悬在半空不参与点钻,并在下一次成功吸取钻石后进行补钻。这种智能化设计不仅杜绝了因空钻或漏钻而需要返工的情况,还无形中大幅降低了成本。

智能蜡镶机不仅提高了生产效率,还确保了饰品出货质量的一致性,满足用户对高质量和高效率的需求。

通过使用智能蜡镶机,珠宝制造企业可以大幅提升生产力,减少人为错误,确保每一件产品都完美无缺。无论是小型工作室还是大型工厂,智能蜡镶机都是提升竞争力的不二选择。

创建时间:2025-01-08 21:00

넶浏览量:0