Diamond Setting Machine: A High-Efficiency Tool in Jewelry Processing Equipment, Making Ornament Production Easier

In recent years, Diamond Setting Machine has become a core device in the jewelry processing sector. It efficiently and accurately completes tasks ranging from simple diamond settings to intricate multi-faceted designs, enhancing production efficiency and reducing labor costs for jewelry manufacturers.

Working Principle of the Diamond Setting Machine

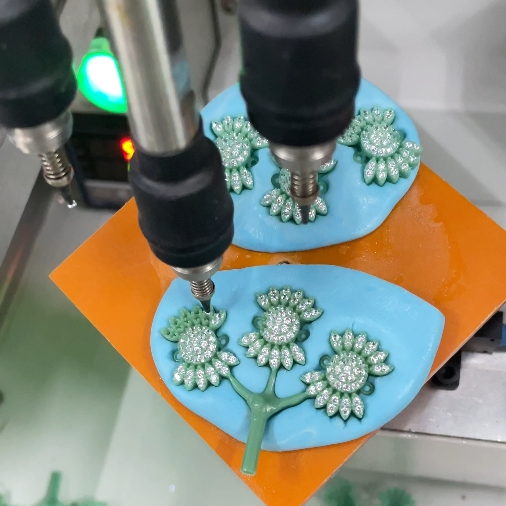

Primarily used in the jewelry setting process, the Diamond Setting Machine embeds gems into wax molds through a CNC precision system. Traditional manual stone setting is time-consuming and labor-intensive. In contrast, modern diamond wax setting machines utilize automation technology, ensuring precise positioning and secure mounting of each gem with an accuracy within 0.01mm, significantly improving the yield of high-quality products.

Advantages of Wax Setting Machines in Ornament Processing

- High Efficiency: Compared to traditional methods, a dual-station, eight-needle diamond wax setting machine by Yubang Technology can complete 36,000 to 40,000 stones per hour, ideal for large volume orders.

- Stable Quality: Automation reduces human error, guaranteeing consistent embedding results. The smart recognition feature of Yubang's machine prevents missed stones, lowering rework rates.

- Versatile Adaptability: Suitable for over 90% of stone-setting styles and supports simultaneous embedding of differently colored and sized diamonds, easily handling both flat and complex three-dimensional designs.

- Reduced Labor Dependence: While training skilled operators takes a long time, the wax setting machine is user-friendly, requiring only brief training for novices, thus cutting down on labor costs.

Application Scenarios of Diamond Setting Machine

- Mass Production: Ideal for the rapid embedding of standard ornaments like rings, bracelets, and pendants.

- Customized Processing: Parameters can be flexibly adjusted to meet diverse jewelry processing needs.

How to Choose the Right Diamond Setting Machine?

When selecting a Diamond Setting Machine, focus on the key indicators of precision, speed, and stability. Yubang Technology’s dual-station, eight-needle machine, with its independent control system, allows for simultaneous debugging and production, significantly reducing downtime and making it an optimal choice for boosting manufacturing capacity.

As a crucial part of jewelry processing equipment, the wax setting machine is driving the ornament processing industry towards greater efficiency and intelligence. Whether for large-scale production or high-end customization, choosing a stable-performing Diamond Setting Machine can greatly enhance jewelry manufacturing.